Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Áit Tionscnaimh:

Zhejiang, an tSín

Ainm branda:

ZK

Réimse Feidhmchláir:

Mótar mol EV, etc.

Ábhar:

NdFeB sintered

Treo maighnéadaithe:

Trí thiús nó saincheaptha

cruth PM:

Dronuilleogach / bloc, fáinne, stua / deighleog nó saincheaptha

MOQ:

1K nó saincheaptha, athraíonn an praghas bunaithe ar ordú QTY

Táille Samplach:

Le plé

Am Luaidhe Táirgeachta:

15-20 lá tar éis íocaíocht a fháil agus sonraí an ordaithe deimhnithe ag an dá pháirtí

+86-15857968349

+86-15857968349

Tá teicneolaíocht feithiclí leictreacha (EV) ag fás go tapa agus ag éirí níos coitianta i margaí ar fud an domhain, agus an India ar cheann de na margadh sin atá ag súil go mór le fás sna blianta amach romhainn. Scrúdóidh an t-alt seo réimsí iarratais agus treochtaí margaidh maighnéid mótair mol roth feithicle leictreacha i margadh na hIndia, agus leagfaidh sé béim ar na buntáistí a bhaineann le Zhejiang Zhongke Magnetic Industry Co., Ltd. Tá na comhpháirteanna seo á ndéanamh aige.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

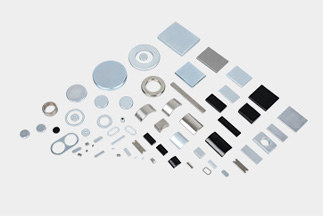

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

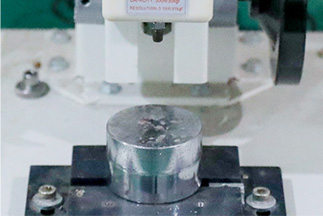

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Tá úsáid maighnéid mótair mol roth feithicle leictreacha ag méadú go tapa san India, áit a bhfuil spriocanna uaillmhianacha leagtha síos ag an rialtas maidir le hastaíochtaí carbóin agus truailliú aeir a laghdú. Go háirithe, tá feithiclí leictreacha á gcur chun cinn san earnáil iompair phoiblí, le tionscnaimh ar nós scéim FAME (Glacadh agus Déantúsaíocht Níos Tapúla Feithiclí Hibrideacha agus Leictreacha) ag tairiscint fóirdheontais agus dreasachtaí do mhonaróirí, chomh maith le hinfheistíocht mhéadaithe i mbusanna leictreacha agus poiblí eile. feithiclí iompair.

Ina theannta sin, tá dhá roth leictreacha ag éirí coitianta san India freisin mar gheall ar a n-inacmhainneacht agus a gcostas reatha íseal. Chruthaigh an t-éileamh méadaitheach ar na feithiclí seo deiseanna do mhonaróirí comhpháirteanna cosúil le mótair mhol roth agus maighnéid.

Táthar ag súil go bhfásfaidh margadh feithiclí leictreacha Indiach ag luas suntasach sna blianta amach romhainn, le CAGR réamh-mheasta de 43.13% ó 2021 go 2026, de réir tuarascála ag Mordor Intelligence. Leagann an tuarascáil béim freisin go bhfuiltear ag súil go mbeidh dhá roth leictreacha ar an gcuid is mó de mhargadh EV Indiach mar gheall ar a n-inacmhainneacht agus brú an rialtais leictriú sa deighleog dhá roth.

Ina theannta sin, tá spriocanna uaillmhianacha leagtha síos ag rialtas na hIndia maidir le feithiclí leictreacha a ghlacadh, agus é mar aidhm aige 30% de na feithiclí go léir a bheith leictreacha faoi 2030. Táthar ag súil go spreagfaidh an sprioc seo, in éineacht le feasacht agus dreasachtaí méadaithe, fás sa mhargadh feithiclí leictreacha agus cruthófar nua. deiseanna do mhonaróirí comhpháirteanna cosúil le mótair mol roth agus maighnéid.

De réir mar a leanann margadh feithiclí leictreacha Indiach ag fás, tá roinnt príomhthreochtaí ann ar dócha go gcruthóidh siad todhchaí mhótair agus maighnéid mol roth feithicle leictreacha. Ceann de na treochtaí is suntasaí is ea an méadú ar úsáid maighnéid tearc-chré sna comhpháirteanna seo. Tairgeann na maighnéid seo airíonna maighnéadacha níos fearr i gcomparáid le maighnéid traidisiúnta, agus mar sin tá siad níos éifeachtaí agus níos éadroime.

Treocht thábhachtach eile is ea an fócas ar inbhuanaitheacht agus laghdú ar thionchar comhshaoil feithiclí leictreacha. Áirítear leis seo úsáid na n-ábhar athchúrsáilte i dtáirgeadh comhpháirteanna cosúil le mótair mol roth agus maighnéid, chomh maith le forbairt dearaí níos tíosaí ar fhuinneamh.

Zhejiang Co Tionscal Zhongke Maighnéadach, Ltd Zhejiang Zhongke Co Tionscal Maighnéadach, Ltd. Is monaróir na príomhchúiseanna le maighnéid bhuan agus comhpháirteanna mótair, lena n-áirítear maighnéid mótair mol roth feithicle leictreacha. Tá roinnt buntáistí tábhachtacha ag an gcuideachta i margadh na hIndia, lena n-áirítear:

1. Raon leathan táirgí: Zhejiang Zhongke Maighnéadach Tionscal Co, Ltd. Tá punann táirgí cuimsitheach aige a chuimsíonn cineálacha éagsúla maighnéid tearc-chré, ó ghrád N go grád ZH, agus d'fhéadfadh cruthanna a bheith i bhfoirm bloc, fáinne, cruth deighleog stua.

2. Teicneolaíocht táirgthe chun cinn: Zhejiang Zhongke Maighnéadach Tionscal Co, Ltd. tá saoráid táirgthe úrscothach aige le trealamh agus teicneolaíochtaí chun cinn a cheadaíonn déantúsaíocht beacht comhpháirteanna agus comhar straitéiseach domhain le hAcadamh Eolaíochtaí na Síne.

3. Cumas láidir T&F: Zhejiang Zhongke Maighnéadach Tionscal Co, Ltd. tá foireann thiomanta T&F aige atá dírithe ar tháirgí nua a fhorbairt agus ar tháirgí atá ann cheana a fheabhsú. Ligeann sé seo don chuideachta fanacht chun tosaigh ar an gcomórtas agus réitigh nuálacha a sholáthar do chustaiméirí.

4. Táirgí ar ardchaighdeán: Zhejiang Zhongke Maighnéadach Tionscal Co, Ltd. tá córas rialaithe cáilíochta dian aige a chinntíonn go gcomhlíonann na táirgí go léir caighdeáin cháilíochta idirnáisiúnta. Cuidíonn sé seo le muinín a bhunú le custaiméirí agus dea-cháil a chothabháil sa mhargadh.

Tá margadh feithiclí leictreacha Indiach ar tí fás suntasach sna blianta atá le teacht, rud a chruthaíonn deiseanna do mhonaróirí comhpháirteanna mar mhótair agus maighnéid mol roth feithicle leictreacha. Zhejiang Co Tionscal Zhongke Maighnéadach, Ltd Zhejiang Zhongke Co Tionscal Maighnéadach, Ltd. tá roinnt príomhbhuntáistí ag baint leis a ligeann dó dul san iomaíocht sa mhargadh seo, lena n-áirítear raon leathan táirgí, ardteicneolaíocht táirgthe, cumas láidir T&F, agus táirgí ardchaighdeáin. De réir mar a leanann an margadh ag forbairt, is dócha go mbeidh Zhejiang Zhongke Magnetic Industry Co., Ltd. beidh ról atá ag éirí níos tábhachtaí maidir le comhpháirteanna ardcháilíochta a sholáthar do thionscal feithiclí leictreacha Indiach.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.